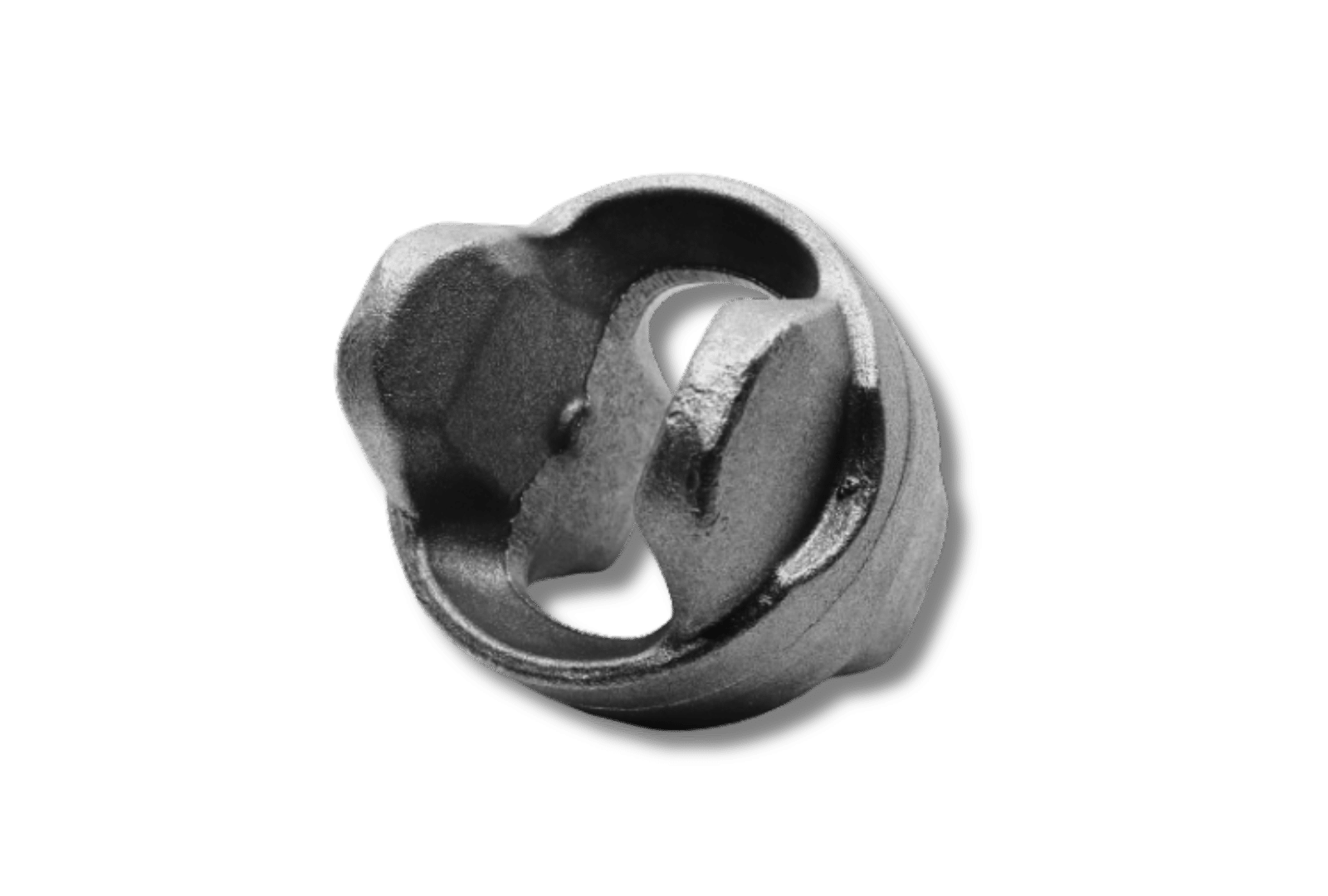

The forged double joint is a key mechanical component in heavy-duty transmission systems.

It ensures a strong connection between two drive shafts, transferring torque and power smoothly, even in cases of significant angular misalignment.

The forged double joint enables:

Compensation of angular offsets between shafts

Smooth torque transmission without power loss

Reduction of vibrations and mechanical stress

Increased reliability in demanding environments

Thanks to the forging process, double joints benefit from superior strength, homogeneous structure, and higher fatigue resistance — essential for intensive applications.

Forged double joints are used in:

Automotive: passenger cars and utility vehicle transmissions

Heavy trucks and buses: robust transmission systems

Agricultural machinery: tractors, harvesters, forestry equipment

Industrial machines: mechanical transmission lines and heavy equipment

Reliable torque transmission under high loads and misalignment

Extended service life of the metal through forging

High resistance to fatigue and torsional stress

Reduced risk of play or structural failure

Versatility: suitable for automotive, agriculture, construction, and heavy industry

With long-standing expertise in hot forging of steels and alloys, Forlam Forge designs and manufactures forged double joints adapted to the needs of automotive OEMs, Tier-1 suppliers, and industrial manufacturers.

Our production ensures:

Maximum robustness under severe operating conditions

Complete traceability of all forged parts

Rigorous quality controls for safety and reliability

Our forged double joints are a durable and reliable solution for the most demanding power transmission applications.