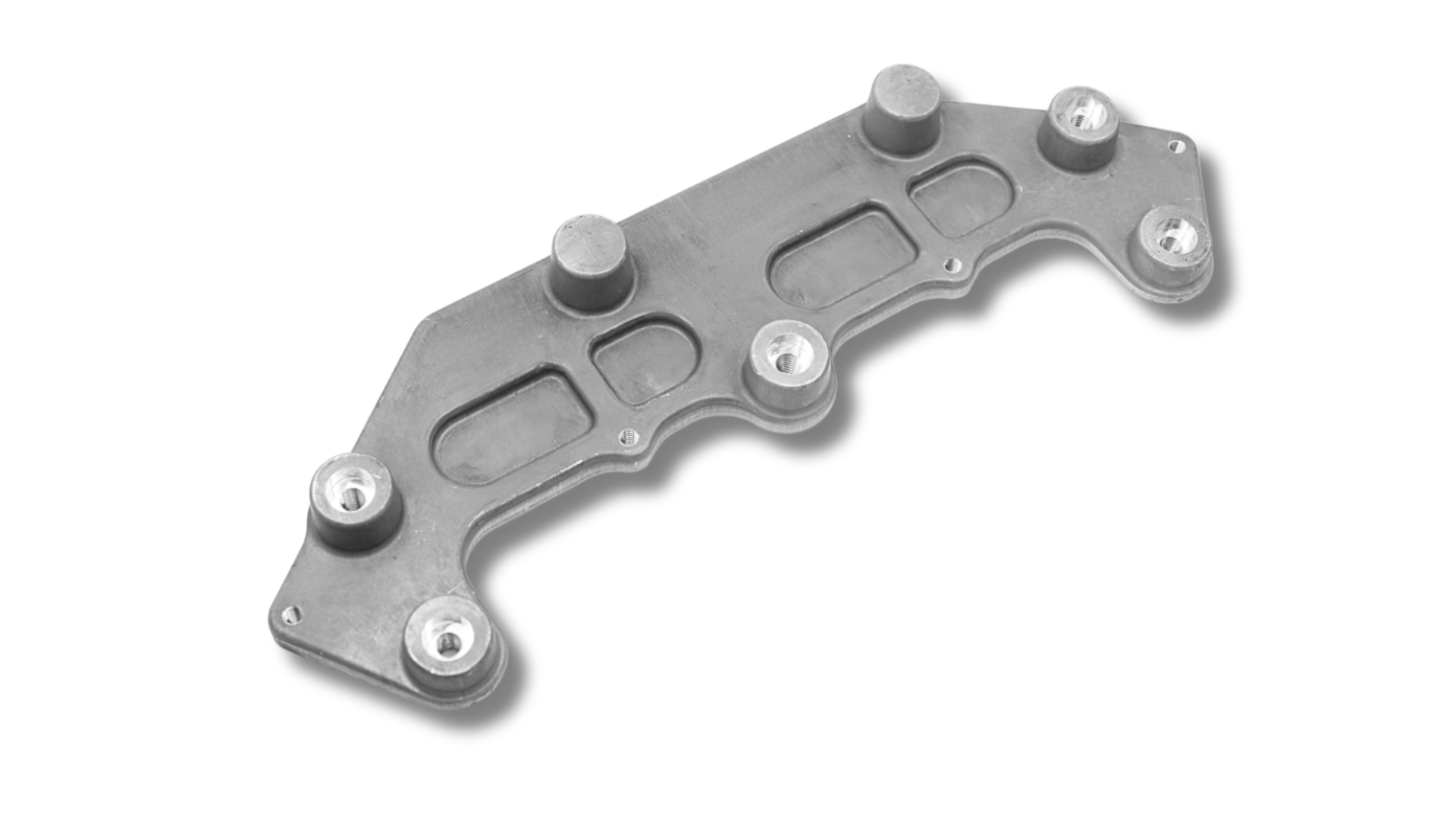

The Bracket Assy is an assembly component used as a battery support specifically designed for electric and hybrid trucks.

This part provides structural reinforcement for the battery modules, and also contributing to the overall weight reduction of the vehicle.

The forged aluminum bracket assy serves several key functions:

Secure attachment and retention of the batterie’s compartment.

Absorption and distribution of mechanical and vibratory stresses.

Structural reinforcement to protect batteries from impact.

Weight optimization to improve the range of electric trucks.

At Forlam Forge, these parts are available in several conditions:

Raw part : integration and machining by the customer.

Machined and treated : ready to assemble with mechanical finishes, heat treatments, and quality controls.

Forged aluminium bracket assy are used in :

Electric trucks with high-capacity batteries.

Hybrid trucks with on-board energy storage.

Specials industrial vehicles (buses, heavy-duty utility vehicles).

Heavy-duty carbon-free mobility systems.

Lightweight and robust : strengthens and lightens the vehicle.

Mechanical strength and fatigue resistance superior to cast parts.

Increased durability, even in difficult conditions (vibrations, shocks).

Dimensional accuracy for reliable and safe assembly.

Adaptability : raw or machined according to the manufacturer’s requirements.

With its expertise in precision aluminum forging, Forlam Forge supports heavy vehicle and industrial equipment manufacturers in the design of structural parts for next-generation electric vehicles.

Our forged bracket assy contribute to the safety, durability, and energy performance of trucks and electric vehicles.

A strategic choice for players in carbon-free transport and reliable electromobility.