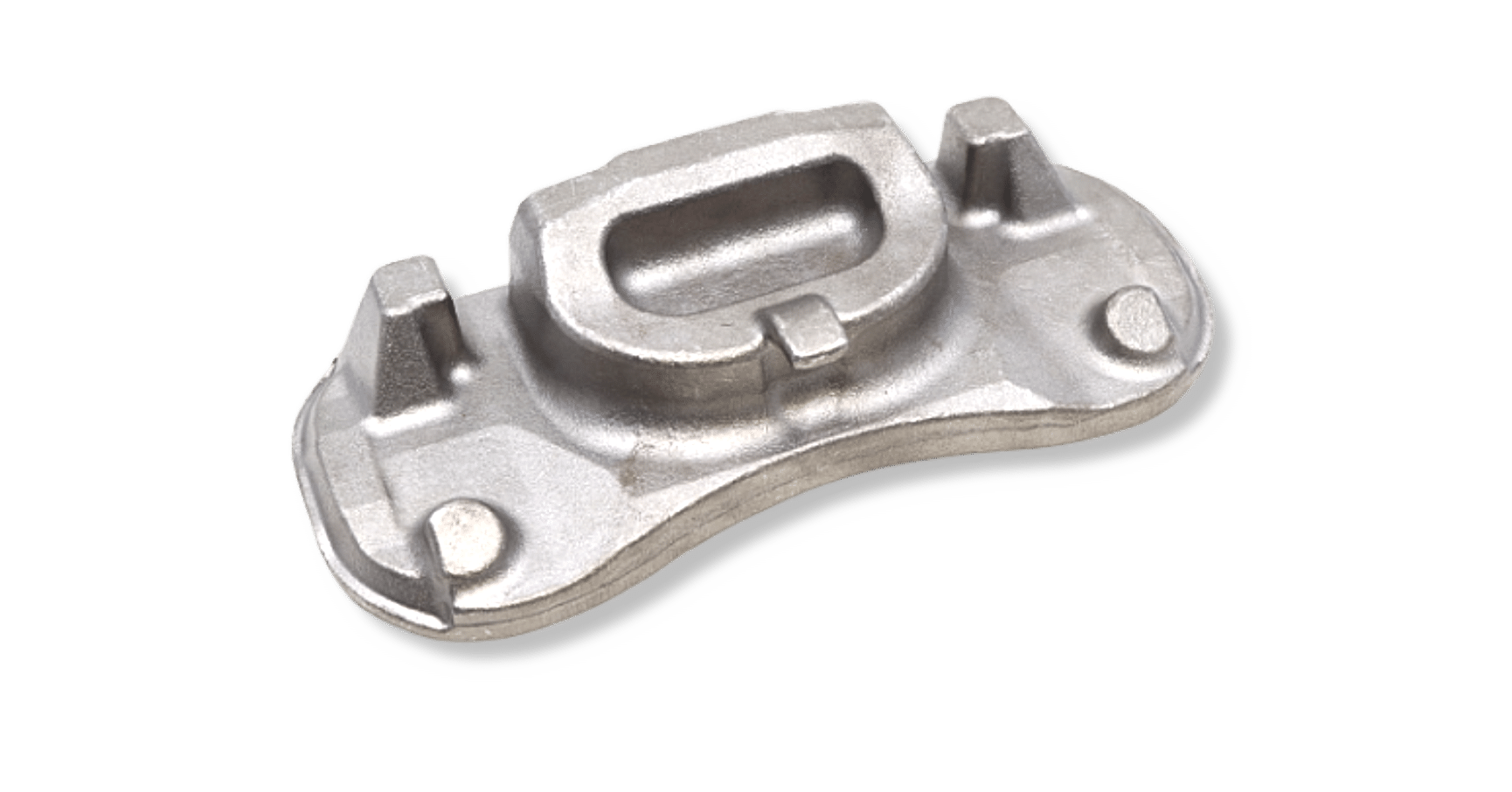

Forged axle bracket is a structural component essential to the chassis of heavy-duty vehicles. Their role is to link, secure, and support the axles, while ensuring optimal load distribution and high mechanical strength.

Thanks to the forging process, axle brackets offer greater strength and extended service life, even under the demanding mechanical and environmental conditions faced by trucks, trailers, and buses.

Our forged axle bracket is designed to withstand:

Heavy and repeated loads (axle and vehicle weight)

Dynamic forces from braking, acceleration, and cornering

Permanent vibrations on roads and highways

Harsh operating conditions (varied climates, dust, humidity, road salt)

Made from carbon steel, they provide:

Optimal mechanical resistance

Superior fatigue performance compared to cast parts

Increased safety, reducing the risk of structural failure

Raw forged: intended for OEMs and industrial vehicle manufacturers integrating further machining and assembly onto chassis systems

Heavy-duty trucks (road transport, construction, logistics)

Buses and coaches (public transport)

Trailers and semi-trailers

Military and special vehicles, operating under extreme conditions

Extreme robustness: suitable for heavy loads and long-distance use

Durability: reduced maintenance and extended vehicle lifespan

Dimensional accuracy after machining

Full traceability of forged batches

Enhanced safety for operators and end-users

As a specialist in hot forging of carbon steels, Forlam Forge produces a wide range of reinforcement parts dedicated to chassis systems of trucks and industrial vehicles.

Our custom-designed forged axle brackets are made for leading European OEMs and Tier-1 suppliers, ensuring safety, reliability, and performance in modern heavy-duty vehicles.

Available in raw forged versions, these parts provide a high-quality foundation for machining and integration into your vehicle platforms.